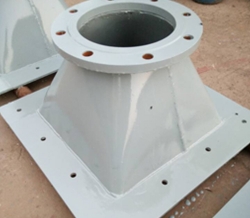

產(chan)品性能(neng):

1、耐磨(mo)性(xing):陶瓷復(fu)合鋼管的內襯(chen)陶瓷層中Al2O3含量大于95%,顯微硬(ying)度HV1000-1500,因而具有極(ji)高(gao)的耐磨(mo)性(xing),其耐磨(mo)性(xing)比淬火后(hou)的中碳鋼高(gao)十余倍,優于鎢(wu)鉆(zhan)硬(ying)質合金。

2、耐腐(fu)(fu)蝕性 陶瓷屬中性材(cai)料,化學性能穩定,具有優異的耐腐(fu)(fu)性和耐酸(suan)(suan)性,可抗各(ge)種無(wu)機酸(suan)(suan)、有機酸(suan)(suan)、有機溶劑等,其抗蝕程度是不銹鋼的十倍以上。

3、耐(nai)熱性能(neng)優異,能(neng)耐(nai)溫2000℃以上,可在-50℃~900℃范圍內長期工作。

4、易焊(han)接(jie):陶瓷(ci)內(nei)(nei)襯復合(he)鋼(gang)管(guan)可以通過焊(han)接(jie)外層鋼(gang)管(guan)達到(dao)連(lian)接(jie)的目(mu)的,陶瓷(ci)內(nei)(nei)襯復合(he)鋼(gang)管(guan)可采(cai)用焊(han)接(jie)、法(fa)蘭、柔性快速接(jie)頭(tou)等聯結方(fang)式,安裝十分方(fang)便。

應用行業(ye):1.要(yao)求高(gao)耐(nai)磨(mo)的管(guan)(guan)道(dao)(dao)(dao)(dao):火力發電、熱電廠灰(渣(zha)(zha))輸(shu)送(song)、煤粉輸(shu)送(song)管(guan)(guan)道(dao)(dao)(dao)(dao),選礦(kuang)廠尾礦(kuang)輸(shu)送(song)和精礦(kuang)輸(shu)送(song)管(guan)(guan)道(dao)(dao)(dao)(dao),港口礦(kuang)漿(jiang)和泥(ni)沙輸(shu)送(song)管(guan)(guan)道(dao)(dao)(dao)(dao),粉煤漿(jiang)輸(shu)送(song)管(guan)(guan)道(dao)(dao)(dao)(dao)等。2.重介(jie)選(洗(xi))煤廠精煤輸(shu)送(song)管(guan)(guan)道(dao)(dao)(dao)(dao),要(yao)求高(gao)耐(nai)腐(fu)蝕性(xing)火力發電脫硫漿(jiang)渣(zha)(zha)輸(shu)送(song)管(guan)(guan)道(dao)(dao)(dao)(dao)。3.熔融鋁液輸(shu)送(song)管(guan)(guan)道(dao)(dao)(dao)(dao)。4.要(yao)求高(gao)耐(nai)磨(mo)、高(gao)耐(nai)腐(fu)蝕、耐(nai)高(gao)溫的各(ge)種(zhong)道(dao)(dao)(dao)(dao)